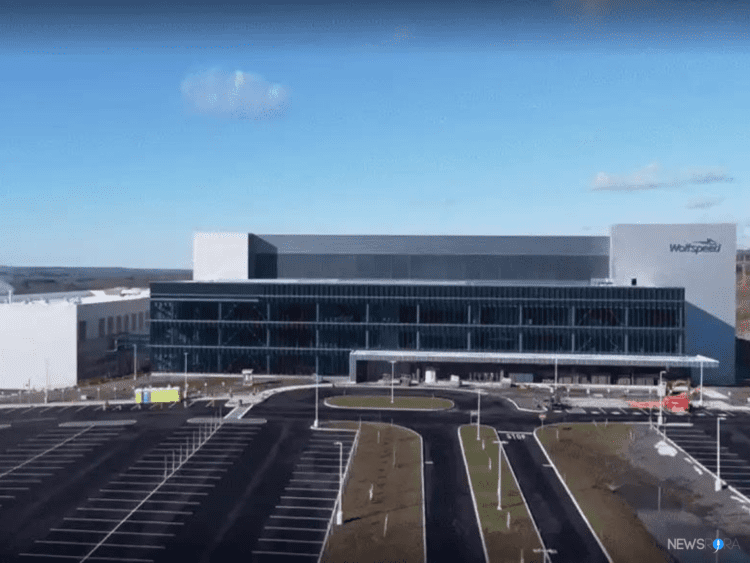

With its gray exterior and large glass windows, the new Wolfspeed factory in upstate New York looks like any other large corporate office building. Inside, however, is a high-tech plant that’s mostly run by robots programmed to manufacture semiconductors with a high degree of precision. This is an entirely different scene from the Ford assembly lines of the 20th century, and it may be the future of American manufacturing, at least according to the politicians and executives who attended the plant’s grand opening.

An estimated few hundred people attended the event in a large tent outside of the factory entrance, including Wolfspeed employees, investors, and local officials. Speakers, including Wolfspeed CEO Gregg Lowe, took turns touting the plant’s importance – for local jobs, for technology, for fighting climate change, and even for American prosperity. Among those at the event was Eric Bach, chief engineer at Lucid Motors, an electric vehicle manufacturer that just hours before announced it would be using Wolfspeed’s chips. The headliner: New York Gov. Kathy Hochul, who said the new facility is part of this country’s “greatest comeback in the history of this nation” before she drove in one of the luxury Lucid EVs.

Wolfspeed’s factory is reopening after a worldwide semiconductor shortage left car parts unavailable and the health care system short of medical devices for over two years. As part of its effort to produce more chips, the Biden administration plans to invest $52 billion in the chip industry to build more factories like the one outside Utica, New York. In addition to making semiconductors, these plants are intended to spur a technology manufacturing renaissance in the same country that produced Silicon Valley decades ago.

Sadly, the new crop of chip factories will not be ready in time to resolve the current chip shortage. They will require many years to build, and even when they are completed, they will not produce as many chips as the United States requires. However, the government believes fabs could play a critical role in blunting the impact of a future crisis, like climate change or another pandemic. As a result, the US could regain its leadership in an industry it created and catch up to Taiwan, which makes almost all of the world’s most advanced chips today.

It’s unclear, however, whether funding the construction of new fabs will be enough to achieve those goals. Building a single fab is a huge undertaking, so building several at once will be an even bigger undertaking. There may be some risk in that the success of these new fabs is still dependent on other parts of the world, as the US is trying to domesticate technology that has, for decades, been produced via an international supply chain made up of thousands of companies. Even as the White House tries to capture a larger share of the world’s chip manufacturing, other countries are trying to do the same thing, so there’s no guarantee the US will end up with the advantage it wants.

Chips on the table

In order for all this to happen, the US must pass the Chips Act, a $52 billion package that would subsidize the construction of several new fabs. Currently, the bill is bundled into a larger proposal called the United States Innovation and Competition Act, legislation focused on competitiveness with China. Republicans, Democrats, the White House, and major chip companies all support the initiative, even though the House and Senate versions aren’t exactly the same. Each of these companies could theoretically receive up to $3 billion to build a new factory, and another $2 billion could be earmarked specifically for a chip factory that would focus exclusively on basic car chips.